您还没有选择分类数据,请先选择数据

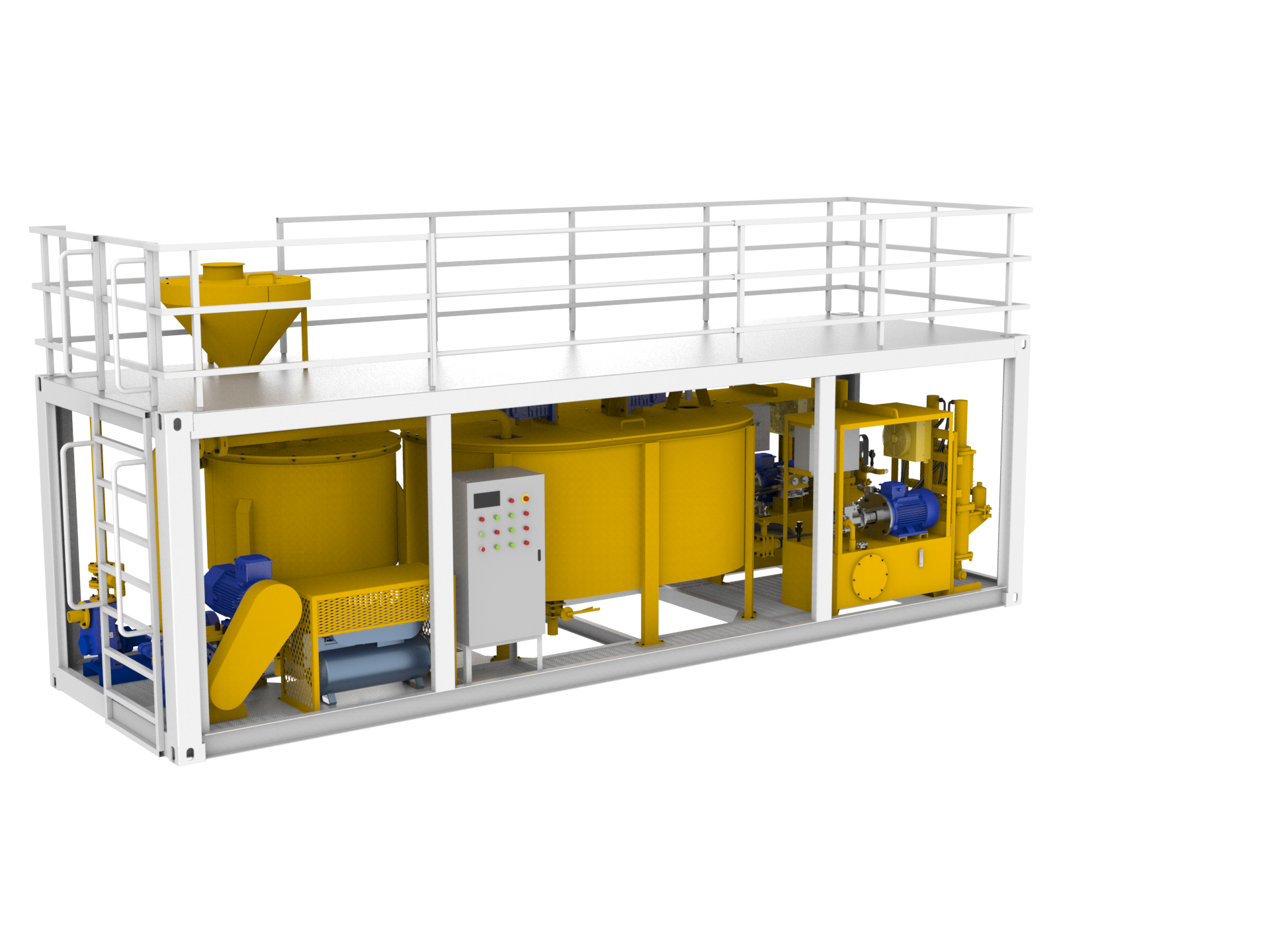

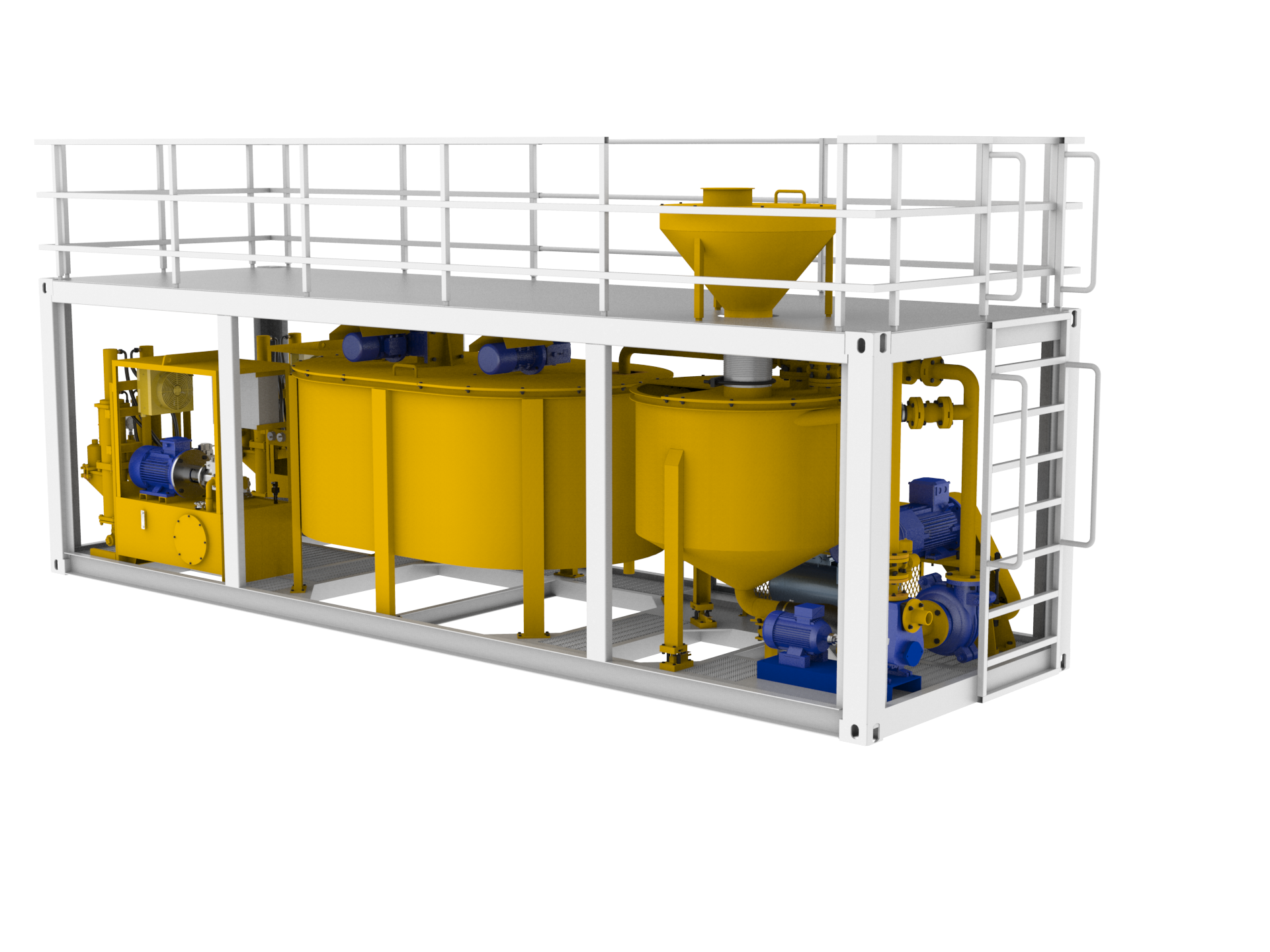

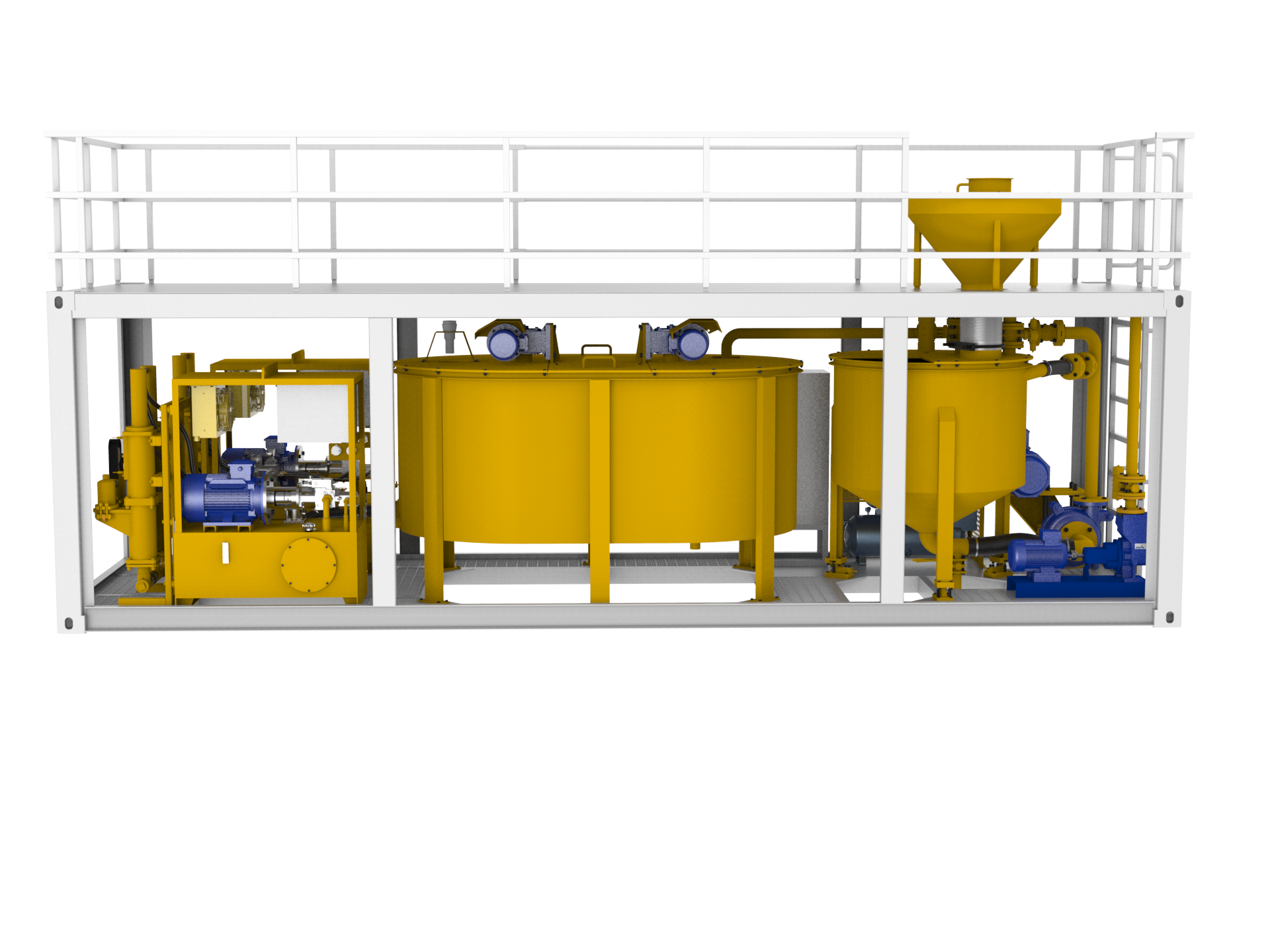

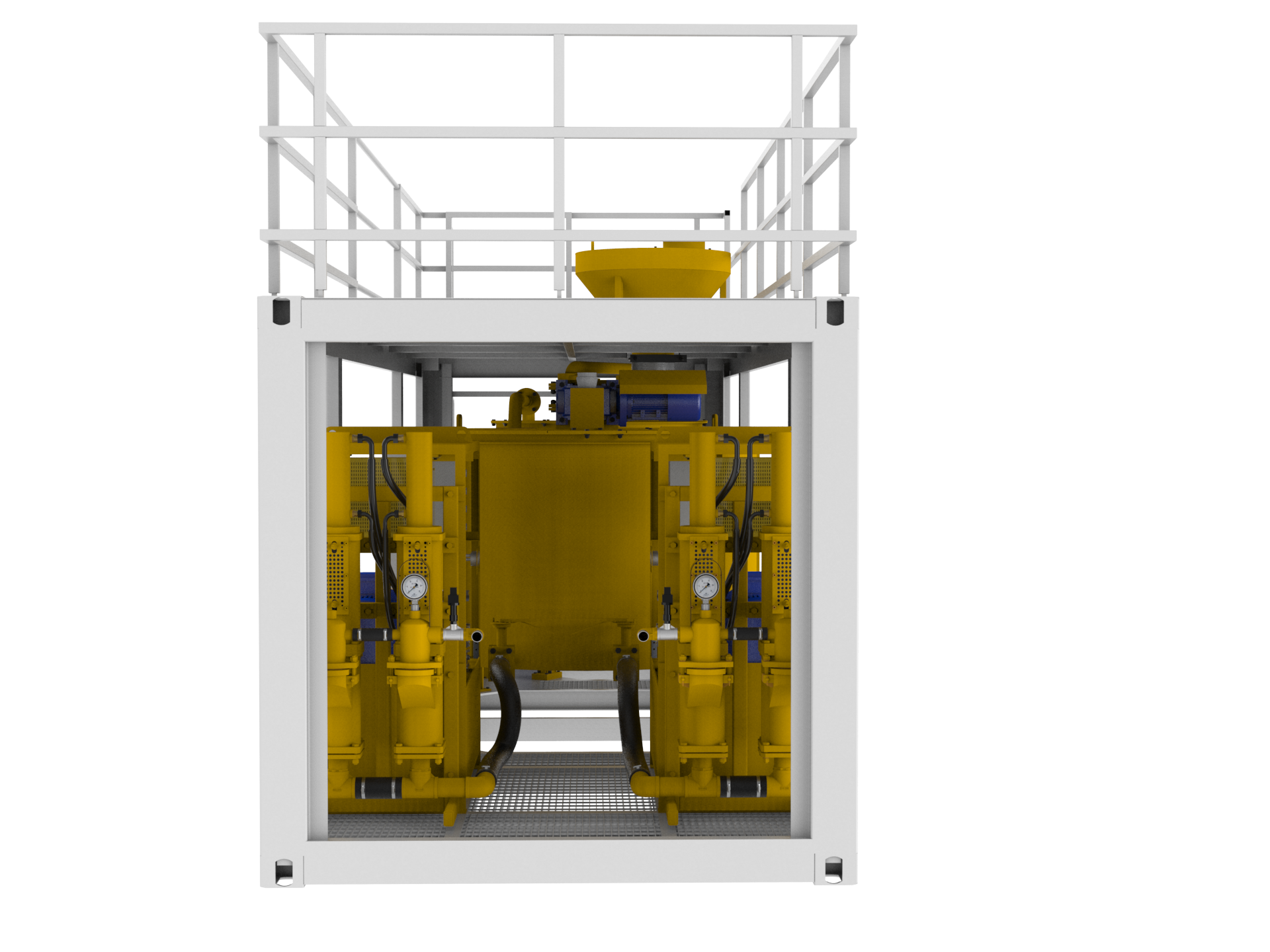

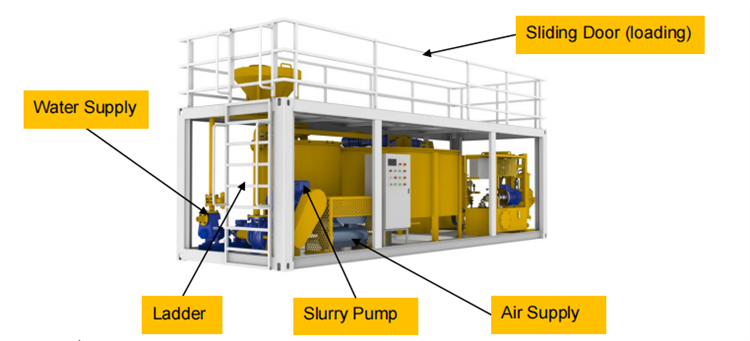

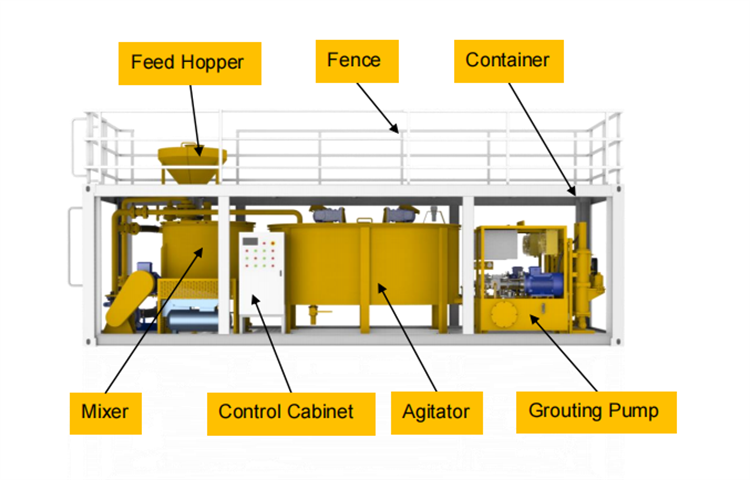

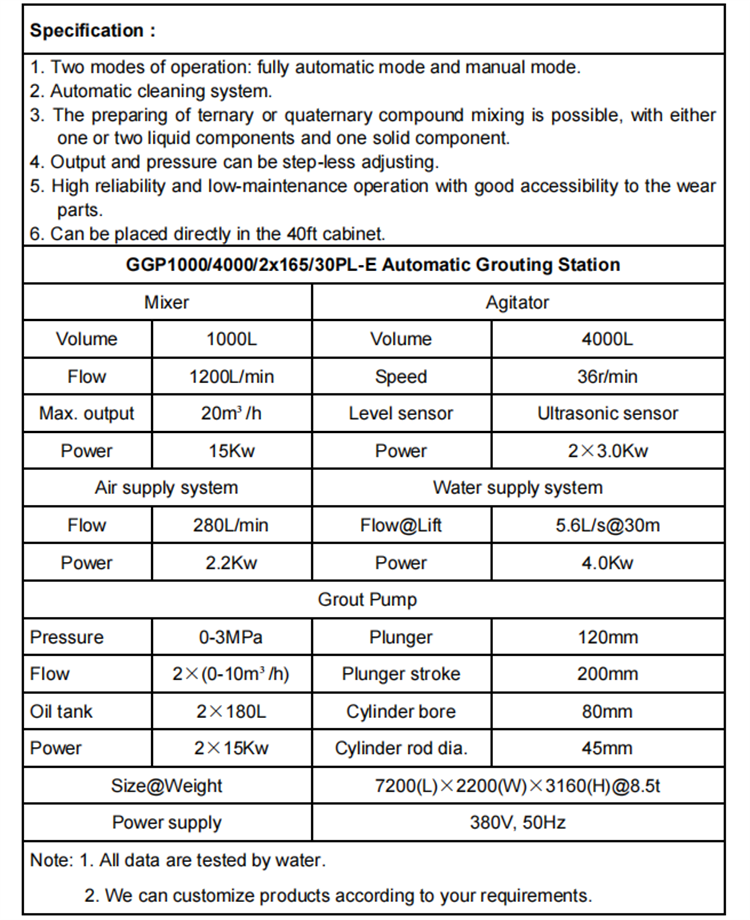

GGP1000/4000/2x165/30PL-E Automatic Grouting Station

Description

GGP1000/4000/2x165/30PL-E Automatic Grouting Station was mainly conceived in order to obtain, through a high turbulence mixing of water and cement powder, a cement mixture (cement grout), or, by using water and bentonite powder, a bentonite sully for plastic muds. Also, the preparation of ternary or quaternary compound mixing is possible, with either one or two liquid components and one solid component. The cement mixture or the bentonite sully is then transferred to the other units by a plunger pump(2 sets to choose), according to the type of foreseen geotechnical machinings.

This setup is suitable for a wide range of applications such as anchoring, sleeve pipe, contact, and backfill grouting or Preparation and pumping of bentonite suspensions for pipe jacking and micro tunneling.

Features:

Main pipeline valves are all pneumatic valves

Mixer, slurry pump and agitator have automatic cleaning function

Cement can be added by screw feeder automatically

The preparing of ternary or quaternary compound mixing is possible, with

either one or two liquid components and one solid components

Two modes of operation: fully automatic mode and manual mode

Output and pressure can be step-less adjusting

High productivity due to ergonomically positioned operating elements

Independent of pressure ratios, the suction stroke is always carried out at

high velocity in order to flush the valves and to avoid clogging

High reliability and low-maintenance operation with good accessibility to

the wear parts

Up to 5mm particle size

Equipped with some ceiling lamps, for illuminating the different working

areas

Can be placed directly in the 40ft cabinet

Technology Sheet

Machine Pictures Gallery